|

An airfoil is a surface designed to obtain lift from the air through which it moves. Thus, it can be stated that any part of the aircraft that converts air resistance into lift is an airfoil. The profile of a conventional wing is an excellent example of an airfoil.

The difference in curvature of the upper and lower surfaces of the wing builds up the lift force. Air flowing over the top surface of the wing must reach the trailing edge of the wing in the same amount of time as the air flowing under the wing. To do this, the air passing over the top surface moves at a greater velocity than the air passing below the wing because of the greater distance it must travel along the top surface. This increased velocity, according to Bernoulli’s Principle, means a corresponding decrease in pressure on the surface. Thus, a pressure differential is created between the upper and lower surfaces of the wing, forcing the wing upward in the direction of the lower pressure.

Within limits, lift can be increased by increasing the angle of attack (AOA), wing area, velocity, density of the air, or by changing the shape of the airfoil. When the force of lift on an aircraft’s wing equals the force of gravity, the aircraft maintains level flight.

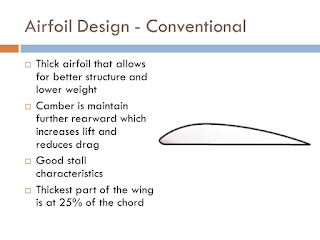

The shape of the airfoil determines the amount of turbulence or skin friction that it produces, consequently affecting the efficiency of the wing. Turbulence and skin friction are controlled mainly by the fineness ratio, which is defined as the ratio of the chord of the airfoil to the maximum thickness. If the wing has a high fineness ratio, it is a very thin wing. A thick wing has a low fineness ratio. A wing with a high fineness ratio produces a large amount of skin friction. A wing with a low fineness ratio produces a large amount of turbulence. The best wing is a compromise between these two extremes to hold both turbulence and skin friction to a minimum.

High-lift wings and high-lift devices for wings have been developed by shaping the airfoils to produce the desired effect. The amount of lift produced by an airfoil increases with an increase in wing camber. Camber refers to the curvature of an airfoil above and below the chord line surface. Upper camber refers to the upper surface, lower camber to the lower surface, and mean camber to the mean line of the section. Camber is positive when departure from the chord line is outward and negative when it is inward. Thus, high-lift wings have a large positive camber on the upper surface and a slightly negative camber on the lower surface. Wing flaps cause an ordinary wing to approximate this same condition by increasing the upper camber and by creating a negative lower camber.

It is also known that the larger the wingspan, as compared to the chord, the greater the lift obtained. This comparison is called aspect ratio. The higher the aspect ratio, the greater the lift. In spite of the benefits from an increase in aspect ratio, it was found that definite limitations were defined by structural and drag considerations.

On each part of an airfoil or wing surface, a small force is present. This force is of a different magnitude and direction from any forces acting on other areas forward or rearward from this point. It is possible to add all of these small forces mathematically. That sum is called the “resultant force” (lift). This resultant force has magnitude, direction, and location, and can be represented as a vector. The point of intersection of the resultant force line with the chord line of the airfoil is called the center of pressure (CP). The CP moves along the airfoil chord as the AOA changes. Throughout most of the flight range, the CP moves forward with increasing AOA and rearward as the AOA decreases. The effect of increasing AOA on the CP.

The AOA changes as the aircraft’s attitude changes. Since the AOA has a great deal to do with determining lift, it is given primary consideration when designing airfoils. In a properly designed airfoil, the lift increases as the AOA is increased.

When the AOA is increased gradually toward a positive AOA, the lift component increases rapidly up to a certain point and then suddenly begins to drop off. During this action the drag component increases slowly at first, then rapidly as lift begins to drop off.

When the AOA increases to the angle of maximum lift, the burble point is reached. This is known as the critical angle. When the critical angle is reached, the air ceases to flow smoothly over the top surface of the airfoil and begins to burble or eddy. This means that air breaks away from the upper camber line of the wing. What was formerly the area of decreased pressure is now filled by this burbling air. When this occurs, the amount of lift drops and drag becomes excessive. The force of gravity exerts itself, and the nose of the aircraft drops. This is a stall. Thus, the burble point is the stalling angle.

ليست هناك تعليقات:

إرسال تعليق