The APU is an alternate source of electrical power and also bleed air. Since it doesn't have any function to generate thrust, it burns considerably less fuel than the engines do, and is intended primarily for ground use, although most APU's can also be operated in flight for things like a second source of electrical power if an engine generator has failed, or a source of bleed air if the bleeds are closed on the engines in order to generate more thrust.

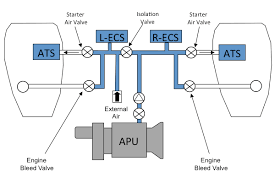

In that diagram, what you're seeing is a portion of the pneumatic system, showing that the bleed air from the APU can be routed to both air conditioning packs (on many aircraft the APU can power both AC packs on the ground; on some aircraft it can only power one at a time), as well as to the engines, where it provides air for starting them.

On some aircraft, the bleed air from the APU can do other things, like pressurizing the water supply, and while it isn't operationally useful, it can generally supply bleed air into the anti-ice ducting for the leading edges. In practice, though, that's only done when the engines are running, due to the greater volume (and temperature) of hot bleed air that the engines can produce compared to the APU.Bleed air is routed to the air conditioning packs where it is filtered and then cooled using an expansion process. The temperature of the air is regulated using uncooled bleed air and the humidity of the mixture is adjusted prior to introducing the air into the aircraft cabin. Temperature controllers in the flight deck and cabin allow adjustment of the target temperature and thermostats provide feedback to the packs to demand an increase or decrease in the output temperature.

Aircraft design has featured bleed air systems for a number of decades. However, with the introduction of the B787, Boeing has incorporated a new no-bleed systems architecture that eliminates the traditional pneumatic system and bleed manifold. Most functions formerly powered by bleed air such as the air-conditioning packs and wing anti-ice systems are now electrically powered. According to Boeing, the no-bleed systems architecture offers operators a number of benefits, including:

Improved fuel consumption due to a more efficient secondary power extraction, transfer, and usage.

Reduced maintenance costs due to elimination of the maintenance-intensive bleed system.

Improved reliability due to the use of modern power electronics and fewer components in the engine installation.

Expanded range and reduced fuel consumption due to lower overall weight.

**Water and Hydraulic System Pressurization

Engine bleed air is used to provide the pressurization needed for the water and hydraulic system reservoirs. Such pressurization propels drinking water from the holding tank to the cabin and ensures the smooth flow of hydraulic fluid to the pump inlet in the absence of sufficient atmospheric pressure at high altitudes.

Source: FAA Handbook

ليست هناك تعليقات:

إرسال تعليق